Products

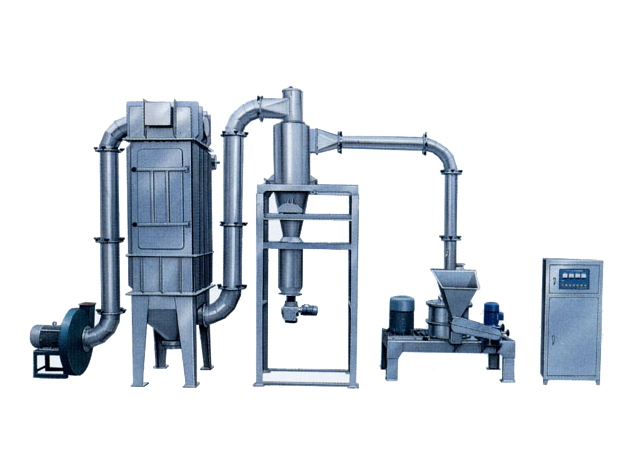

WFJ Series Mini-efficient Pulverizer

Features

Material is transported into crushing chamber by screw conveyor and crashed by high-speed rotating cutter. Transporting material into helix separated machine by negative pressure and discharging material through bag deduster. The powder is filtered and recycled by cloth bag. There is no flying dust during producing process, it improves the utilization ratio of material and reduces the production cost of company.

Technical Parameters

| Model | WFJ-15 | WFJ-30 | WFJ-60 | WFJ-80 |

| Production capacity(kg/h) | 40-150 | 80-400 | 150-1000 | 200-1500 |

| Feed size(mm) | <10 | <10 | <10 | <10 |

| Discharge size(mesh) | 40-300 | 40-300 | 40-300 | 40-300 |

| Total power(kw) | 18.32 | 44 | 81 | 103 |

| Main rotating speed(r/min) | 5500 | 3650 | 2900 | 2300 |

| Weight (kg) | 1300 | 2000 | 4000 | 5500 |

Write your message here and send it to us