Products

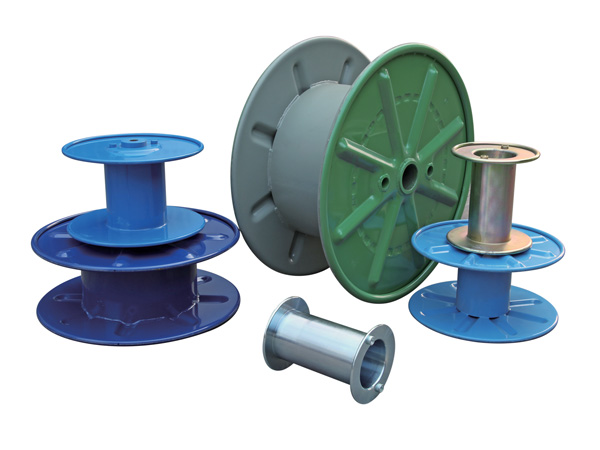

Spools bobbin reel (wooden /Iron /Plastic)

Product List

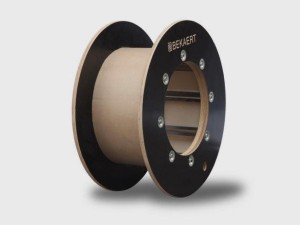

Wooden Cable Spool

Steel Cable Drum

Steel and Wood Cable Drum

Plywood cable drum

Plastic Cable Drum

Application

Spools of various specifications and structures are customized according to customer requirements. It is applicable to the steel wire rope, cable, optical fiber photo chloride and other production processes and the packaging of finished products. Excellent dynamic balance performance, suitable for high-speed take-up and pay-off. Export to Japan, EU and other countries.

Feature

Steel spools: In accordance with GB4004-83, JB/T7600.3-94 and DlN46395 standards, the steel spool is made of common carbon steel plate through assembly and welding, and machine finishing. The product has high rigidity of bobbin and high precision. Through dynamic test, the product has stable operation at high speed, and can be used for high-speed drawing-wire machine and wire stranding machine with better overall strength, high dimensional accuracy, structural stability.

In order to ensure the stability of each bobbin during high-speed rotation, we will measure the dynamic balance of each bobbin. For the bobbin with unstable operation, we will increase the balance block to make it run smoothly.

Wooden spools: Fasten Hopesun provides various wooden spools like solid wooden spool, standard micro cable bakelite spool, bakelite spool, etc. provided by us is highly demanded over its optimum quality and high strength. Our wide range of Wooden Cable Drums is available in different shapes and sizes. These Cable Drums which we provide are used in Cable Industry for manufacturing optical fiber cable and electrical cables.

Plastic spool: Plastic processing reels are mainly made of engineering plastics with composed structure. It is suitable for the take up and pay off of the bunching, extrusion, twisting, wrapping and cabling equipment in the production process of photoelectric cable. For different procedures, we have enhanced, heave-duty, high-speed dynamic balance type and large capacity type to meet customer's requirement. Plastic reel has the advantages of the light weight, smooth, high strength, high impact, anti-acid, corrosion and balance performance, etc., and it has obvious comparative advantages with the wooden drum and steel bobbin, which meets the conditions for alternative use.

Quality control

Pre-production: Workers need to be familiar with the design of spools, then jointly examine the drawings with the technical director.

Under production: In conjunction with the operator to do a good job of witness sampling, examining raw materials, and then be clear about every quality control emphasis in the working procedure of cable reel.

After production: Leak filling and improve the quality inspection information of the finished cable drums.