Products

Renewable Design For Wire Copper Plating Production Line - Customized automobile high-precision parts – Fasten

Renewable Design For Wire Copper Plating Production Line - Customized automobile high-precision parts – Fasten Detail:

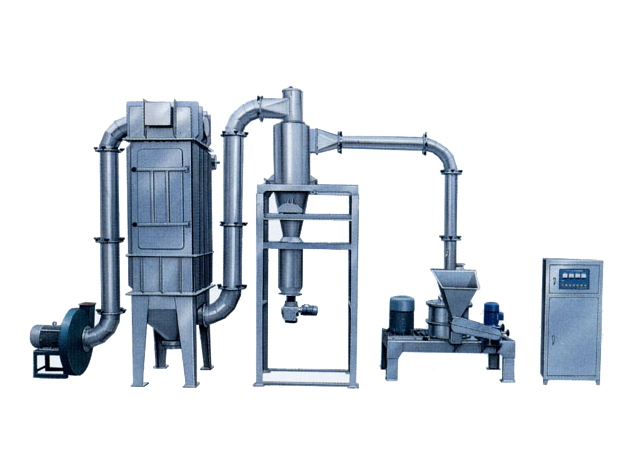

Production equipment

Japan star12-star32 series CNC Automatic Lathe

The CNC vertical machining center workbench is 400*600, mainly used for milling and drilling, and is effectively used for the processing of precision components of automobile and motorcycle engines.

Coreless Grinder Machine

Maximum grinding diameter 40 mm, grinding precision 5um, polishing accuracy 1.53um

Testing equipment

Coordinates Device

Accuracy: 0.0001mm

Projection Detector

Why choose us

We have a number of advanced processing equipment, including GRU32x80 gantry boring and milling machine, DMG MORI NHC5000 horizontal machining center, DMG MORI CTX510 turning center, vertical machining center, DMC1035V TOS VARNSDOR horizontal boring and milling center and other imported large equipment for key tooling. There are more than 50 Japanese STAR series CNC automatic lathes, more than 40 grinders, 5 automatic 250t-500t CNC die casting equipment and a large number of common machining equipment.

There are 3 coordinate detector, Emerson CSI2130 online dynamic balance and vibration detector, CU10 hole shape detector imported from Norway and a batch of measuring projector, which guarantee the quality of equipment.

The quality of equipment is strictly in accordance with ISO9001 standard. All materials are purchased under incoming quality control, the main parts are famous brands and will be tested by inspection personnel according to product quality control. The final products are confirmed to meet the users’ requirements and provided with qualification certificate.

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Renewable Design For Wire Copper Plating Production Line - Customized automobile high-precision parts – Fasten , The product will supply to all over the world, such as: Iran, Congo, France, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!