Products

Perforated steel strip PE pipe For water supply

Application

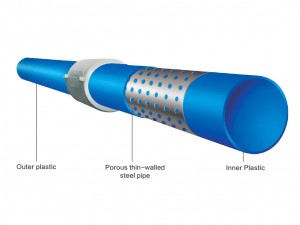

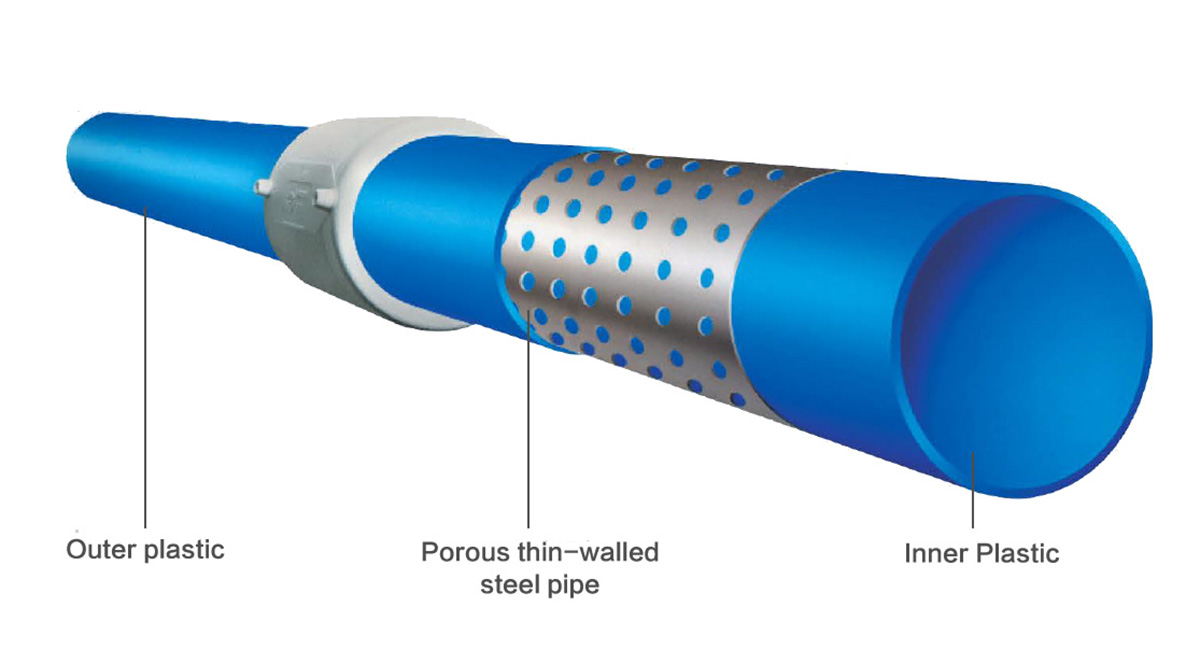

Perforated steel strip polyethylene composite pipe is made of cold-rolled strip steel and thermoplastics as raw materials, and porous thin-walled steel pipes formed by argon arc butt welding or plasma spiral welding are used as reinforcements. The outer and inner layers are double-sided composite thermoplastics. A new type of composite pressure pipe, Because the porous thin-walled steel pipe reinforcement is wrapped in continuous thermoplastic, this composite pipe not only overcomes the respective shortcomings of steel pipes and plastic pipes, but also has the rigidity of steel pipes and the corrosion resistance of plastic pipes. It is a solution for petroleum and chemical industries. It is an urgently needed pipeline of large and medium-diameter rigid pipes in the fields of pharmaceutical, food, mining, gas and other fields. It is also a revolutionary technological achievement to solve the main pipeline of construction and municipal water supply. It is a new type of composite pipeline in the 21st century.

Features

High strength and low linear expansion.

Due to the reinforcement of the steel frame, the perforated steel strip plastic composite pipe has higher strength, high rigidity and impact resistance than the plastic pipe. At the same time, the restraint effect of the steel frame also makes the perforated steel strip plastic composite pipe have а low line similar to that of the steel pipe. Expansion coefficient and сгеер resistance.

Corrosion and wear resistance.

The high-density polyethylene material selected for the perforated steel strip plastic composite pipe is а crystalline non-polar polymer material with stable chemical properties, resistance to most acid, alkali salts and organic media, and по electrochemical corrosion. The grinding performance is 5 times higher than that of steel pipes.

Technical Parameters

This product uses special polyethylene resin, and its physical and mechanical properties meet the Ministry of construction standard CJ/T181-2003 and the chemical industry standard HG/T3706-2014.

|

Specification size, deviation and nominal pressure: meet the requirements of the Ministry of construction standard CJ/T181-2003 |

|||||

|

Nominal outer diameter and deviation |

Nominal wall thickness and deviation |

Out of roundness |

Nominal pressure |

Minimum S value |

Length and deviation |

|

Dn(mm) |

En(mm) |

Mm |

Mpa |

Mm |

mm |

|

50+0.5 0 |

4.0+0.5 9 |

1.0 |

2.0 |

1.5 |

6000+20 0 9000+20 0 12000+20 0 |

|

60+0.6 0 |

4.5+0.6 0 |

1.26 |

2.0 |

1.5 |

|

|

75+0.7 0 |

5.0+0.7 0 |

1.5 |

2.0 |

1.5 |

|

|

90+0.9 0 |

5.5+0.8 0 |

1.8 |

2.0 |

1.5 |

|

|

110+1.0 0 |

6.0+0.9 0 |

2.2 |

2.0 |

1.5 |

|

|

140+1.1 0 |

8.0+1.0 0 |

2.8 |

1.6 |

2.5 |

|

|

160+1.2 0 |

10.0+1.1 0 |

3.2 |

1.6 |

2.5 |

|

|

200+1.3 0 |

11.0+1.2 0 |

4.0 |

1.6 |

2.5 |

|

|

225+1.4 0 |

11.5+2.4 0 |

4.5 |

1.6 |

2.5 |

|

|

250+1.4 0 |

12.0+1.3 0 |

5.0 |

1.6 |

3.5 |

|

|

280+1.5 0 |

12.5+2.6 0 |

5.6 |

1.6 |

3.5 |

|

|

315+1.6 0 |

13.0+1.4 0 |

6.3 |

1.25 |

3.5 |

|

|

355+1.6 0 |

14.0+2.8 0 |

7.1 |

1.25 |

3.5 |

|

|

400+1.6 0 |

15.0+1.5 0 |

8.0 |

1.25 |

3.5 |

|

|

500+1.7 0 |

16.0+1.6 0 |

10.0 |

1.0 |

4.0 |

|

|

630+1.8 0 |

17.0+1.7 0 |

12.3 |

1.0 |

4.0 |

|

|

Note: The nominal pressure of the composite pipe is the maximum pressure allowed for the pipe to transport water at 20°С. If the temperature changes, the working pressure should be corrected according to the temperature pressure coefficient of different materials. S value: the distance from the outer diameter of the reinforcement to the outer surface of the pipe. |

|||||

| Physical and mechanical performance requirements | ||

| Project | Performance | |

| Ring stiffness, KN/m2 | >8 | |

| Flat test | Not broken | |

| Longitudinal shrinkage (100°С, maintain 1h) | <0.3% | |

| Hydraulic test | Temperature: 20°С; Time: 1h; Nominal pressure x2 | Not broken |

| Temperature: 80°С; Time: 165h; Pressure: Nominal pressure x2x0.71 (reduction factor) | ||

| Burst pressure test | Temperature: 20°С, burst pressure ≥ nominal pressure x3.0 | Blasting |

| Oxidation induction time (200°С), min | ≥20 | |

| *Weather resistance*

Cumulative acceptance of pipes≥3.5J/m2 After aging energy |

Hydraulic test, the experimental conditions are the same as item 3 in this table | Not broken |

| Burst pressure test, the test conditions are the same as item 4 in this table | Not blast | |

| Oxidation induction time (200°С), min | ≥10 | |

*Only for blue composite pipe*