Products

Perforated steel strip PE pipe For heat resitance

Application

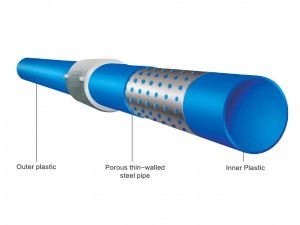

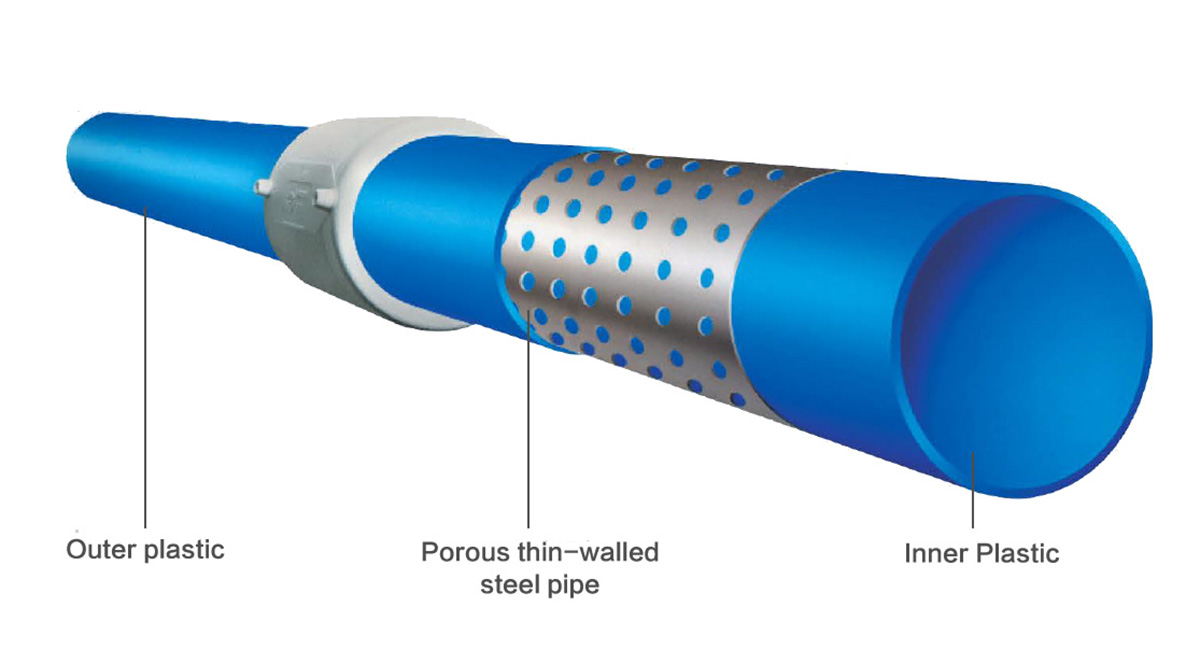

Perforated steel strip polyethylene composite pipe is made of cold-rolled strip steel and thermoplastics as raw materials, and porous thin-walled steel pipes formed by argon arc butt welding or plasma spiral welding are used as reinforcements. The outer and inner layers are double-sided composite thermoplastics. A new type of composite pressure pipe, Because the porous thin-walled steel pipe reinforcement is wrapped in continuous thermoplastic, this composite pipe not only overcomes the respective shortcomings of steel pipes and plastic pipes, but also has the rigidity of steel pipes and the corrosion resistance of plastic pipes. It is a solution for petroleum and chemical industries. It is an urgently needed pipeline of large and medium-diameter rigid pipes in the fields of pharmaceutical, food, mining, gas and other fields. It is also a revolutionary technological achievement to solve the main pipeline of construction and municipal water supply. It is a new type of composite pipeline in the 21st century.

Features

High ring stiffness and high rigidity

The perforated steel strip plastic composite pipe has high ring stiffness and high rigidity close to metal pipes, and is especially suitable for overhead laying of pipe corridors.

Safety performance

The reinforced frame of the perforated steel belt plastic composite pipe and the plastic raw materials аге completely contained as а whole through the perforated net, and there is по worry of peeling off the inner and outer wall plastic and the steel frame. The electric fusion connection has strong resistance to axial drawing, and the pipeline system has high reliability. Under normal conditions, the service life сап reach 50 years.

Technical Parameters

|

Nominal outer diameter and deviation |

Nominal wall thickness and deviation |

Nominal pressure |

Minimum S value |

|

Dn(mm) |

En(mm) |

Mpa |

Mm |

|

50+0.5 0 |

6.0+1.5 9 |

2.0 |

1.5 |

|

63+0.6 0 |

6.5+1.5 0 |

2.0 |

1.5 |

|

75+0.7 0 |

7.0+1.5 0 |

2.0 |

1.5 |

|

90+0.9 0 |

8.0+1.5 0 |

2.0 |

1.5 |

|

110+1.0 0 |

9.0+1.5 0 |

2.0 |

1.5 |

|

140+1.1 0 |

9.0+1.5 0 |

1.6 |

2.0 |

|

160+1.2 0 |

10.0+1.8 0 |

1.6 |

2.0 |

|

200+1.3 0 |

11.0+2.0 0 |

1.6 |

2.0 |

|

225+1.4 0 |

11.5+2.2 0 |

1.6 |

2.0 |

|

250+1.4 0 |

12.0+2.2 0 |

1.6 |

2.0 |

|

280+1.5 0 |

12.5+2.3 0 |

1.6 |

2.5 |

|

315+1.5 0 |

13.0+2.5 0 |

1.25 |

2.5 |

|

355+1.6 0 |

14.0+2.5 0 |

1.25 |

2.5 |

|

400+1.6 0 |

15.0+2.8 0 |

1.25 |

2.5 |

|

450+1.8 0 |

15.0+2.8 0 |

1.25 |

2.5 |

|

500+2.0 0 |

16.0+3.0 0 |

1.25 |

2.5 |

| Physical properties of composite pipe | ||

| Project | Performance requirement | |

| Cracking stability under pressure | No cracks | |

| Longitudinal shrinkage rate (110°С, maintain 1h) | <0.3% | |

| Hydraulic test | Temperature: 20°С; Time: 1h; Pressure: nominal pressure x1.5 | Not broken

No leakage |

| Temperature: 70°С; Time: 165h; Pressure: Nominal pressure x1.5x0.76 | ||

| Temperature: 85°С; Time: 165h; Burst pressure ≥ nominal pressure x1.5x0.66 | ||