Products

China Oem Grinding Machine - Pickling and phosphating (boronizing) production line – Fasten

China Oem Grinding Machine - Pickling and phosphating (boronizing) production line – Fasten Detail:

Feature

High production capacity, high efficiency, low consumption, few operation faults and less area requirement, low consumption, high automation.

Parameters

|

1 |

Pay-off: load the wire rod on the production line. |

|

2 |

Water seal & Degreasing: Degreasing and cleaning the wire rods entering the production line to wash away the oily attachments on the surface. |

|

3 |

Water seal & Degreasing: Degreasing and cleaning the wire rods entering the production line to wash away the oily attachments on the surface. |

|

4 |

Rinsing: Clean the wire rod after degreasing to remove oils. |

|

5 |

Pickling: Remove the oxide layer on the surface of the wire rod, chemical reaction. |

|

6 |

Rinsing: Clean the wire rod after pickling to remove some residual acid and ferrous iron. |

|

7 |

Rinsing: Further cleaning the wire rod surface. |

|

8 |

High pressure spraying: To perform high-pressure washing on the inner and outer surfaces of the wire rod to remove residual acid and ferrous ions on the surface of the wire rod. |

|

9 |

Surface conditioning: Remove most of the ferrous iron and iron compounds remaining on the surface of the wire rod after pickling; Facilitate the formation of phosphating film with fine and compact grains; Improve the adhesion of phosphate coating. |

|

10 |

Phosphating: Form a phosphate film on the surface of the wire rod. |

|

11 |

High pressure spraying: Remove the phosphating liquid and slag on the wire rod after phosphating. |

|

12 |

Rinsing: Remove the phosphating liquid and slag on the surface of the wire rod after spraying. |

|

13 |

Boronizing: Neutralize the residual acid on the surface of the wire rod. Formed a loose and porous puffed coating on wire rod surface convenient for wire drawing. |

|

14 |

Liming: Neutralize the residual acid on the surface of the wire rod. Formed a liming coating on wire rod surface convenient for wire drawing. |

|

15 |

Saponification: Saponify the surface of the wire rod. |

|

16 |

Drying: Dry the surface of the wire rod. |

|

17 |

Take-up: Unload the processed wire rods from the production line. |

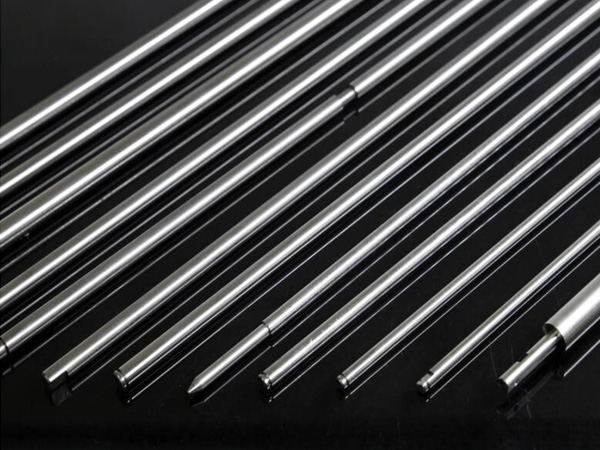

Product detail pictures:

Related Product Guide:

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for China Oem Grinding Machine - Pickling and phosphating (boronizing) production line – Fasten , The product will supply to all over the world, such as: Colombia, Estonia, kazan, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

Write your message here and send it to us