Products

2021 New Style Phosphating Production Line - Pickling and phosphating (boronizing) production line – Fasten

2021 New Style Phosphating Production Line - Pickling and phosphating (boronizing) production line – Fasten Detail:

Feature

High production capacity, high efficiency, low consumption, few operation faults and less area requirement, low consumption, high automation.

Parameters

|

1 |

Pay-off: load the wire rod on the production line. |

|

2 |

Water seal & Degreasing: Degreasing and cleaning the wire rods entering the production line to wash away the oily attachments on the surface. |

|

3 |

Water seal & Degreasing: Degreasing and cleaning the wire rods entering the production line to wash away the oily attachments on the surface. |

|

4 |

Rinsing: Clean the wire rod after degreasing to remove oils. |

|

5 |

Pickling: Remove the oxide layer on the surface of the wire rod, chemical reaction. |

|

6 |

Rinsing: Clean the wire rod after pickling to remove some residual acid and ferrous iron. |

|

7 |

Rinsing: Further cleaning the wire rod surface. |

|

8 |

High pressure spraying: To perform high-pressure washing on the inner and outer surfaces of the wire rod to remove residual acid and ferrous ions on the surface of the wire rod. |

|

9 |

Surface conditioning: Remove most of the ferrous iron and iron compounds remaining on the surface of the wire rod after pickling; Facilitate the formation of phosphating film with fine and compact grains; Improve the adhesion of phosphate coating. |

|

10 |

Phosphating: Form a phosphate film on the surface of the wire rod. |

|

11 |

High pressure spraying: Remove the phosphating liquid and slag on the wire rod after phosphating. |

|

12 |

Rinsing: Remove the phosphating liquid and slag on the surface of the wire rod after spraying. |

|

13 |

Boronizing: Neutralize the residual acid on the surface of the wire rod. Formed a loose and porous puffed coating on wire rod surface convenient for wire drawing. |

|

14 |

Liming: Neutralize the residual acid on the surface of the wire rod. Formed a liming coating on wire rod surface convenient for wire drawing. |

|

15 |

Saponification: Saponify the surface of the wire rod. |

|

16 |

Drying: Dry the surface of the wire rod. |

|

17 |

Take-up: Unload the processed wire rods from the production line. |

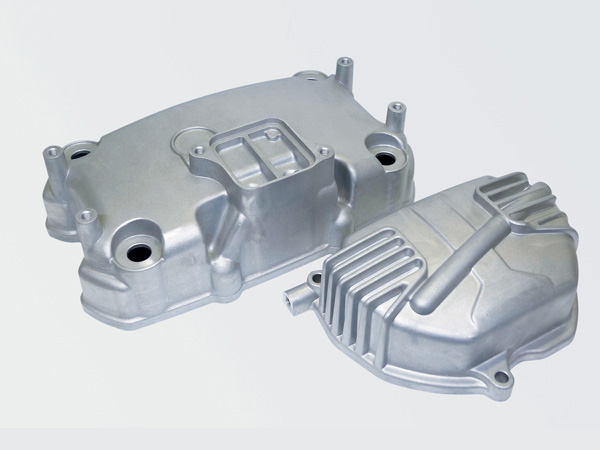

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for 2021 New Style Phosphating Production Line - Pickling and phosphating (boronizing) production line – Fasten , The product will supply to all over the world, such as: USA, Sheffield, Singapore, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Write your message here and send it to us